Whether at sea or on land: VEGAPULS 6X level sensor ensures safety in applications with liquefied gas

Many in the transport industry consider LNG to be the fuel of the future – the fact that it produces hardly any particulate matter and significantly lower greenhouse gas emissions, is a valuable ecological argument. The economic advantages of LNG (short for Liquefied Natural Gas) and LPG (Liquefied Petroleum Gas), when compared to conventional fuels, are generating increased interest in liquefied gases.

LNG is already especially popular in the shipping industry. More and more container and cruise ships are using natural gas as their propulsion fuel. However, when liquefied gas is involved, safety is the top priority – because it is extremely cold, flammable and explosive. The measured values from the VEGAPULS 6X level sensor help to reduce risks and optimise processes. But there are a whole range of other challenges:

1. Robust materials required

✅ Temperature

✅ Density

✅ Pressure

The radar sensor is extremely robust – which is a must when handling LNG. Its metallic structure is composed of durable stainless steel, which thermally decouples the sensitive electronics inside. Thanks to the secure shielding from the process, the sensor can deliver precise measured values down to a temperature of -196 °C. The housing and the front-flush antenna cover of PTFE are suitable for cryogenic applications as well as aggressive media such as acids and alkalis.

2. Small dielectric constants

3. Separability required

In applications with liquified gas, it is often required that the sensors be isolatable from the process via a valve assembly, without the process having to be interrupted. The measuring instruments are capable of being mounted on ball valves. The narrow focussing of VEGAPULS 6X microwave signal ensures that the ball valve has no influence on the level measurement..

Safety at all levels

Safety is the be-all and end-all when it comes to conveying, processing, storing and delivering LNG and LPG. VEGAPULS 6X offers a comprehensive safety concept that fulfils these requirements.

- Functional safety: The level sensor features exceptional SIL characteristics and ensures the necessary operational safety.

- Cybersecurity: VEGAPULS 6X meets the strictest requirements for secure communication and access control with the IEC 62443-4-2 standard.

- Self-diagnosis: The radar sensor has its own system for self-diagnosis. It detects whether the functionality of the sensor is impaired in any way, which supports higher availability and performance of the measuring instrument.

LNG and LPG are becoming more and more important in the transport industry

No matter what stage in the production process these liquids are in – be it storage, purification or final delivery: The high quality of the sensor data helps minimise potential risks.

Applications

LPG spherical tank

Level and pressure monitoring in liquid gas tanks

LPG tanks are usually only accessible for service and maintenance work every few years during shut-down periods. In addition, the containers are mostly installed underground or covered with earth. The solution is a process independent measuring system that delivers safe and reliable readings despite low dielectric constants and low temperatures.

Reliable

High measuring accuracy despite low dielectric constants

Cost effective

Maintenance-free operation

User friendly

Sensor replacement even during operation thanks to cut-off valve

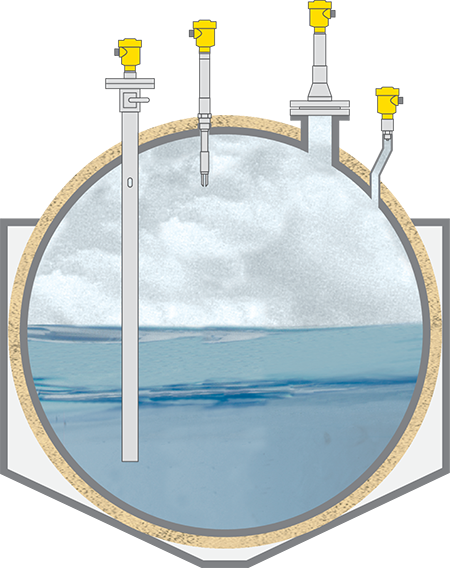

Cargo tanks on LNG carriers

Pressure, level and point level detection in Liquefied Natural Gas (LNG) applications

Liquefied gas is transported in insulated cargo tanks on LNG carriers at temperatures of -162 °C. The instrumentation used must be specially designed for these extreme temperatures. Pressure, level and point level of LNG in the cargo tanks must be reliably measured for the transport.

Reliable

Reliable and safe measurement in all media

Cost effective

Full utilization of the tank volume

User friendly

Simple planning and commissioning

Products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}