Safety at the highest level

What is SIL?

SIL stands for Safety Integrity Level: But it is also sometimes referred to as Safety Requirement Level. In process automation, there are two important standards

- Basic standard for functional safety: IEC 61508

- Sector standard for the application of functional safety in the process industry: IEC 61511

They set the standard for uniform and comparable assessment of devices and process engineering systems. The SIL level is determined by means of a risk assessment, for example by taking the following aspects into account:

- Possible extent of damage

- Length of time people spend in the danger zone

- Options for hazard control

- Likelihood of occurrence

The required SIL level defines how extensive the individual measures must be in order to reduce the risk posed by the processing facility to a tolerable residual risk. Depending on the degree of risk reduction required, users can choose between four different SIL levels: SIL1, SIL2, SIL3 and SIL4. In principle, the following applies: The higher the SIL level of a system, the lower the probability of dangerous faults occurring in the system that would restrict the required safety functions. All components of the safety chain – including the field devices for level, switching and pressure measurement – must meet the specifications for the processing system as a whole.

VEGAPULS 6X and SIL – a perfect match!

Numerous diagnostic functions in the instrument continuously ensure that dangerous faults are detected by the instrument at an early stage. In the rare event of an instrument malfunction, the VEGAPULS 6X radar sensor automatically switches to the safe state and thus provides maximum safety in systems that require SIL-qualified sensors for level measurement. The level sensor is suitable for use up to SIL2; if used in redundancy, for example two VEGAPULS 6X installed in parallel, it is even suitable for use up to level SIL3.

Applying its wealth of experience in 80-GHz technology, VEGA launched a completely new development for VEGAPULS 6X that consistently fulfils the requirements of functional safety right from the start. The instrument manufacturer has built up extensive application expertise in 80-GHz technology and exploits the key advantages in terms of

- focussing

- dynamic range

fully. The SIL version of VEGAPULS 6X is hardly affected by

- condensation

- steam and dust

- dirt and contamination

- turbulent surfaces or

foam. Also available in a hygienic version, it is suitable for both liquids and bulk solids.

Is SIL always the right choice? With VEGAPULS 6X, definitely!

Setup made easy

Armed against cyber attacks

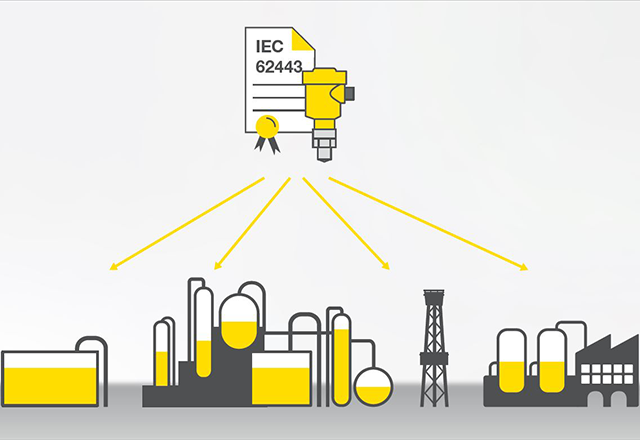

Functional safety is just one of the level sensor’s security components. VEGAPULS 6X is also armed against external attacks. This is necessary, because as digitalisation becomes more commonplace in process automation, cyber attacks increase and become more of a threat. VEGAPULS 6X also offers comprehensive protection in this area. The measuring instrument is certified according to IEC 62443-4-2. It thus meets the highest standards when it comes to cybersecurity.

In a nutshell:

Functional safety protects people from the machine, cybersecurity protects the machine from people. VEGAPULS 6X thus makes a significant contribution to safety in the process industry – at all levels.

Products

Related posts

Precise measurement data? Absolutely – and absolutely secure!

Read moreExport this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}