Sticky, dusty, challenging: The VEGACAP 65 level switch measures the level undeterred

The production of PVC powder presents many challenges: The powder is extremely dusty, and besides that, the individual grains are sticky, adhering not only to each other, but to the measuring instrument as well. For this reason, the point level sensor that measures the levels in the hopper must be robust, precise and permanently reliable. The solution for INEOS Inovyn: VEGACAP 65 with 4 ... 20 mA output.

VEGA’s capacitive sensor for point level detection has multiple advantages

- Buildup is detected early

- Users can calibrate the sensor themselves at any time

- Always enough supplies in stock

- Less buildup thanks to flexible “surfaces”

- Simple mounting and setup

Early detection:

By presetting certain threshold values for detection at the current output of the sensor, the control system is able to interpret the values correctly. As a result, buildup is recognised right from the start.

Calibration:

VEGACAP 65 can be calibrated by the user himself by adapting the minimum and maximum values, together with the values with existing buildup, to the local requirements. For this purpose, the output signal can be easily adjusted. The point level sensor can be recalibrated and adjusted to the desired detection position at any time. This means that, for each application, one replacement sensor in stock is enough to guarantee uninterrupted production.

Flexible “surfaces”:

The “surfaces” of the sensor, with which the level is determined, are partly flexible. So, they can move and bend, which causes part of the deposits to fall off – the result is that the powder builds up much more slowly than with tuning fork sensors with rigid surfaces.

VEGACAP 65 on an input hopper: The measurement remains unaffected, even in case of powder buildup around the sensor.

Applications

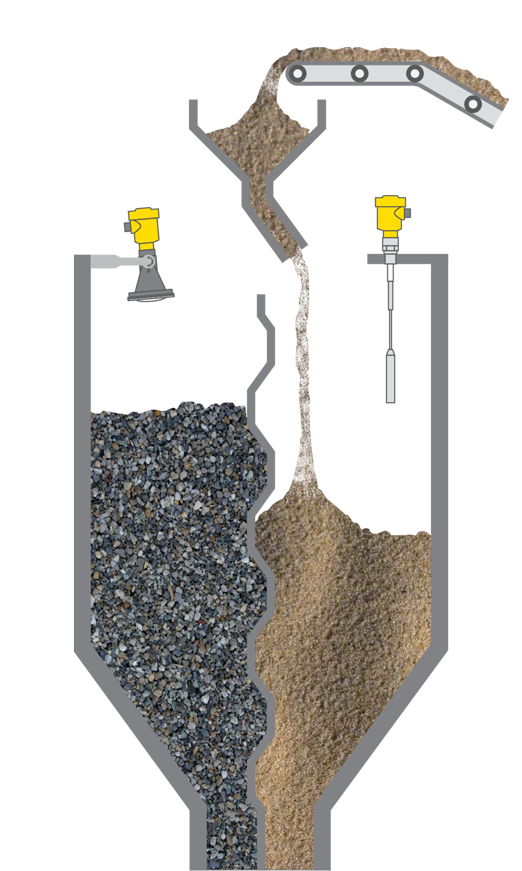

Silo for ready mixed asphalt

Level measurement and point level detection in ready mixed asphalt silos

Different qualities are required from the asphalt depending on the usage and climatic conditions, so every asphalt mixture varies depending on the application. Asphalt is always extremely viscous, hot and highly adhesive. Due to these properties and the numerous different asphalt mixtures, reliable level measurement and point level detection methods are essential.

Reliable

Reliable measuring results even at high temperatures

Cost effective

Optimal utilization of storage capacity

User friendly

Simple installation

Mixing tower

Level measurement and point level detection in mixing towers

Materials such as concrete and mortar are needed in widely different compositions depending on the application. The various raw materials are stored in segmented towers, which then blend cement, lime and other aggregates according to specific requirements. In each individual segment, reliable level measurement and point level detection ensure the constant availability of the raw materials and cost-effective operation of the plant.

Reliable

Reliable measurement in all types of media

Cost effective

Optimal material storage

User friendly

Maintenance-free operation

Products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}