VEGABAR, VEGAWELL, VEGADIF: Hydrostatic level measurement

How does hydrostatic level measurement work?

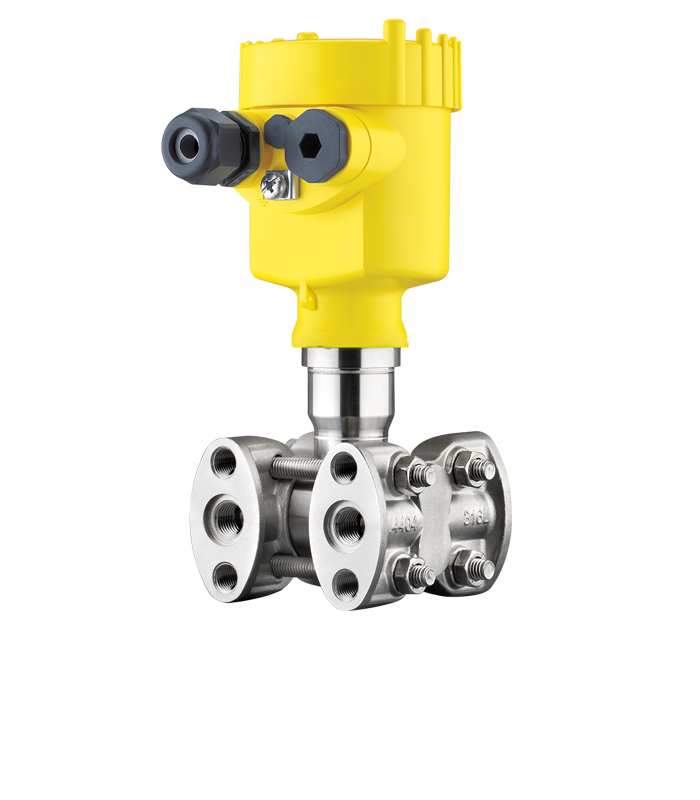

The submerged measurement cell measures hydrostatic pressure, which provides an indirect liquid level measurement

Hydrostatic pressure refers to the mass of a stationary liquid at a given point of measurement. As level increases inside a tank, the hydrostatic pressure increases proportionally. Thus, the higher the hydrostatic pressure measurement, the higher the liquid level measurement.

Making this measurement requires installing a pressure transmitter on a tank so the instrument’s measuring cell is submersed in liquid. The transmitter measures hydrostatic pressure and converts it to a level measurement reading based on the equation below.

Height (Level) = Hydrostatic pressure/(Liquid density * Specific gravity)

What are the advantages of hydrostatic level transmitters?

Hydrostatics have been in use in the process control industry for a long, long time. They are field-proven and familiar to users in many industries. Hydrostatic level instruments provide a reliable, accurate liquid level measurement even through adverse conditions in a tank such as foam, agitation, and obstructions. Users do not have to consider dielectric constant, and the instruments are easy to calibrate.While hydrostatic level measurement is a process automation mainstay, the sophistication of the sensors is constantly increasing. Users are now empowered to choose the best measurement cell material for their process. For example, VEGA offers dry ceramic measuring cells for abrasion resistance and durability as well as metallic measuring cells allow for reliable measurement of many different liquids.

What are common applications for level measurement using hydrostatic pressure sensors?

Application examples for hydrostatic level measurement

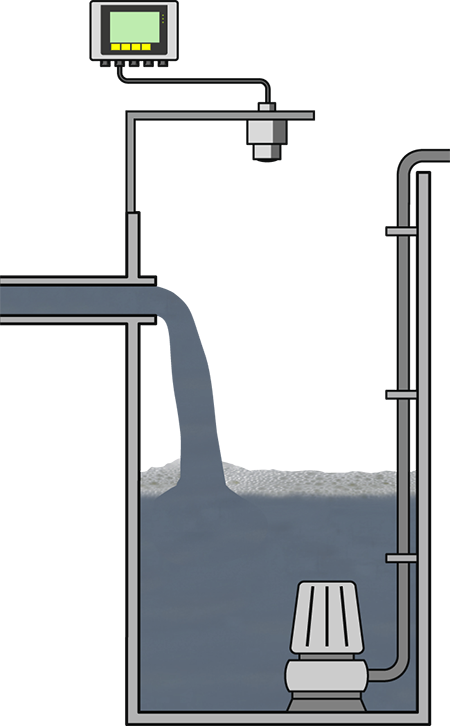

Pumping station

Level control in a pumping station

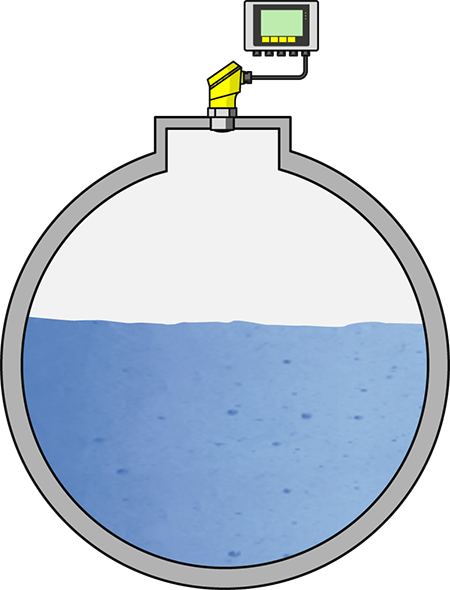

To the applicationProcess water tank

Level measurement in the process water tank

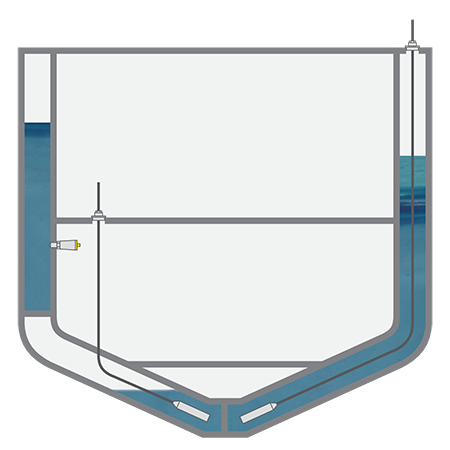

To the applicationBallast water tanks

Level measurement in the forepeak, wing and double bottom tanks with ballast water

To the applicationDiscover the possibilities for hydrostatic level measurement in your industry

Water and wastewater

Oil and gas offshore

Close