Good measurement, good yoghurt

The goal: Produce the tastiest yoghurt. But how do you do that? Well, there is a way to do it, and it’s much different from the methods of the big market leaders in the food industry. La Fageda, located in the Garrotxa district, is one of the region's largest employers. Of the 310 employees, 180 have access needs, learning difficulties, or mental health conditions. Hardly anyone here can handle eight-hour workdays, yet management provides an appropriate job for everyone. Since 2009, the company's turnover has grown by an average of 5% annually. In 2017, it was about 20 million euros. The company, whose product portfolio includes not only yoghurt but also ice cream, jams and desserts, has long since made a name for itself outside Catalonia. International delegations come every day to get informed about the plant. There are now around 40,000 visitors per year. Although La Fageda also benefits from public grants and the cooperation with private companies, these account less than 10% of total revenue.

Guided radar measurement for strict hygiene requirements

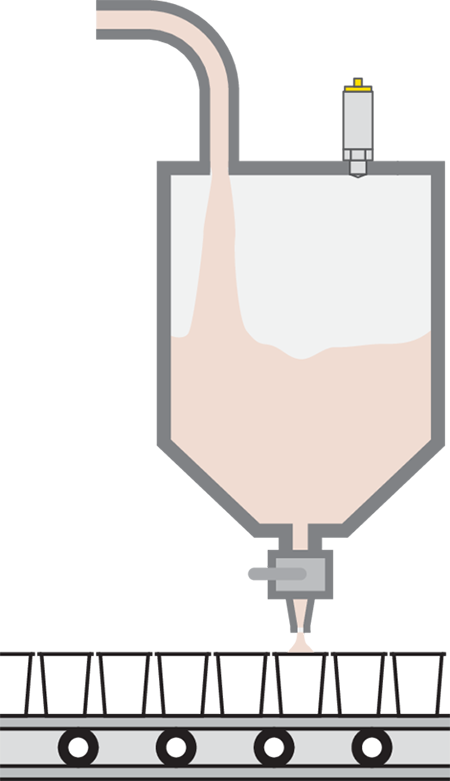

Supply tank of a filling machine

Level measurement and point level detection in the supply tank of a filling machine

Yoghurt is stored in the supply tank of the filling machine. Reliable level measurement and point level detection are important for maintaining the filling process. A point level sensor is also used to prevent dry running of the supply to the machine.

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Continuous filling process, thanks to a reliable measurement

User friendly

Simple installation and setup

VEGAFLEX is non-sensitive to foam, buildup, pressure, vacuum and high temperatures

The strong focusing and wide dynamic range of VEGAPULS 64 ensure reliable measured values

CIP systems are essential for absolutely hygienic production. VEGA sensors continuously measure the level of the cleaning agent for the cleaning and sterilisation of the production equipment.

The extremely tight focusing and high dynamics of the sensor enable precise, reliable measurement in the cleaning fluid tanks. Also at this measuring point, no continuous level measuring device had ever been used − only capacitive sensors that signalled the minimum and maximum level. These are still used as alarm sensors. However, the company wanted to optimize the process flow here too, and utilize the advantages of continuous level measurement.

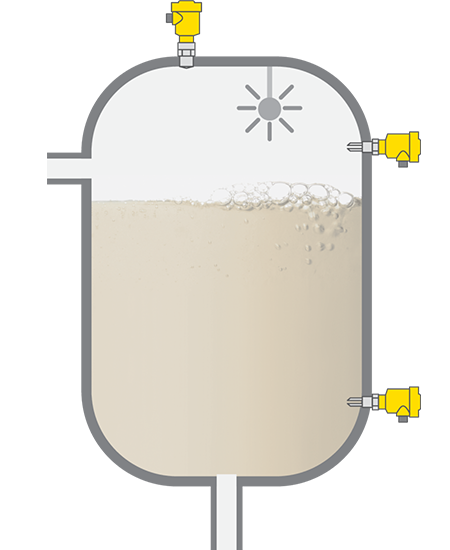

Cleaning agent storage tank of the CIP system

Level measurement and point level detection in the cleaning agent storage tank of the CIP system

The cleaning of process equipment in the food industry takes place within the framework of validated "Cleaning in Place (CIP)" processes that ensure aseptic conditions in production tanks. Sodium hydroxide or concentrated acid are frequently used as cleaning agents, which are stored in the storage tank of the CIP system and diluted in the production vessel. Level measurement enables optimal storage of these cleaning agents. Point level detection serves as overfill and dry run protection.

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Maintenance-free operation

User friendly

Simple mounting

Related products

Related industries

Food industry

Related articles

Radar level transmitter VEGAPULS 64 measures the level in whey production

Read moreExport this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}