Larger measuring ranges for bulk solids level measurement

Is there such a thing as a universal sensor for bulk solids?

Radar sensors are used in widely different applications, ranging from small bulk solids containers to large warehouses. Up to now, meeting the different application requirements meant that different sensor versions had to be used. Is this still necessary?

The theory

The larger the measuring range, the larger the radiated area. But at the same time, the reflected signals are weaker. These issues make strong focusing and a high dynamic range all the more important.

The solution

The measuring range is an indication of the performance capability of the entire system. Due to its particularly good signal focusing and high dynamic range, VEGAPULS 69 can detect poorly reflecting bulk solids reliably, even at a distance of 120 m. That’s with a cycle time of less than one second and an accuracy of ±5 mm.

This system is also designed to achieve the very same performance even over very small measuring ranges.

The benefits

- High performance over small measuring ranges

- Ideal for very high tanks or Silos

- Up to 120 m for level or distance measurement

Expert tip:

With its simple mounting bracket for easy installation, the VEGAPULS 69 with its plastic antenna is perfectly suited for distance measurement.

Applications

Silos for bulk solids

Level measurement and point level detection in silos

In the chemical industry, many different kinds of bulk solids are produced or used as raw materials. To ensure reliable measurement of silo contents, many factors must be considered: different bulk densities, abrasive properties, dust generation and the requirements of explosion protection. Implementation of the most suitable level sensors ensures optimal production planning and reliable logistics for the finished products.

Reliable

Reliable measurement, independent of media properties and container geometry

Cost effective

Maintenance-free operation

User friendly

Universally applicable for almost all bulk solids

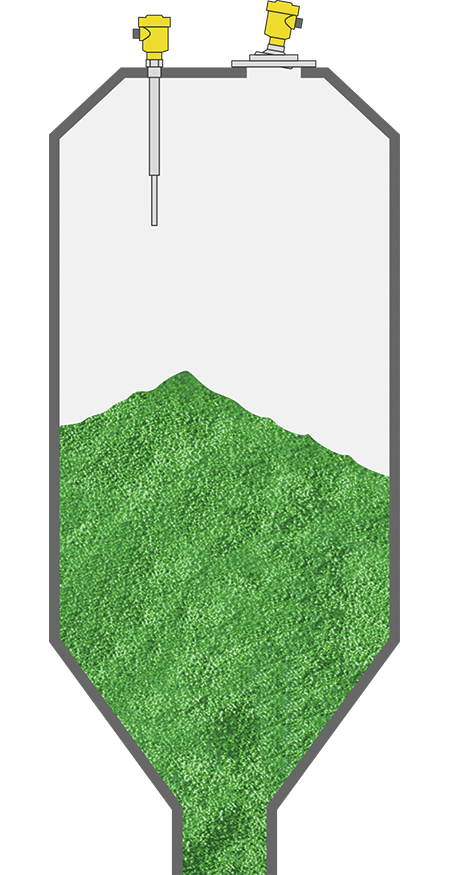

Alumina powder silo

Level measurement and point level detection in alumina powder silos

The alumina powder is kept ready in storage and day silos for subsequent smelting. Aluminium smelting is carried out in the fused salt electrolysis process, where pure liquid aluminium is extracted from aluminium oxide. Optimal storage is ensured by level measurement and point level detection.

Reliable

Reliable content measurement of alumina

Cost effective

Maintenance-free operation

User friendly

Simple mounting and setup

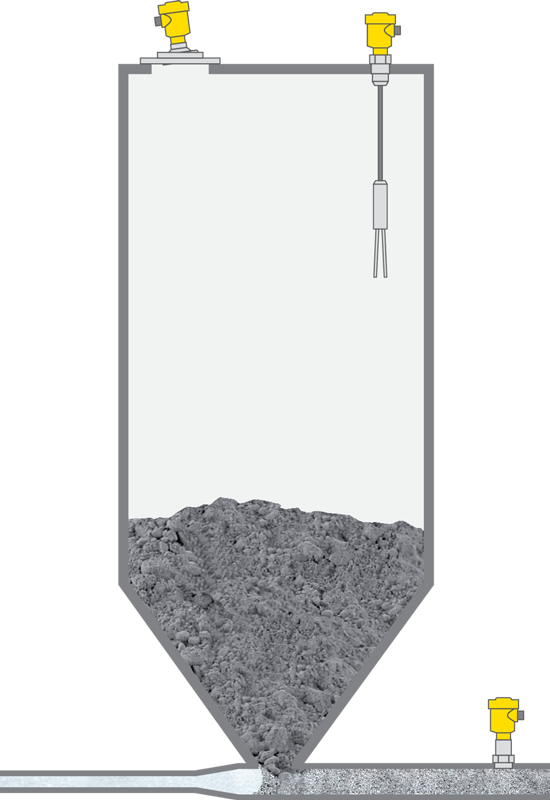

Cement silo

Level and pressure measurement and point level detection in cement silos

Before further processing, the cement is stored in tall silos. The cement is transported both in and out of the silo via pneumatic conveying. Efficient storage and transport of the product is ensured by accurate level measurement and point level detection, as well as also monitoring the pneumatic conveying system pressure.

Reliable

Reliable measurement ensures a continuous supply of raw material

Cost effective

Optimal stocks enable continuous production

User friendly

Maintenance-free operation

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}