Precise pressure sensors for measuring tasks of all kinds

Sensors with ceramic measuring cell

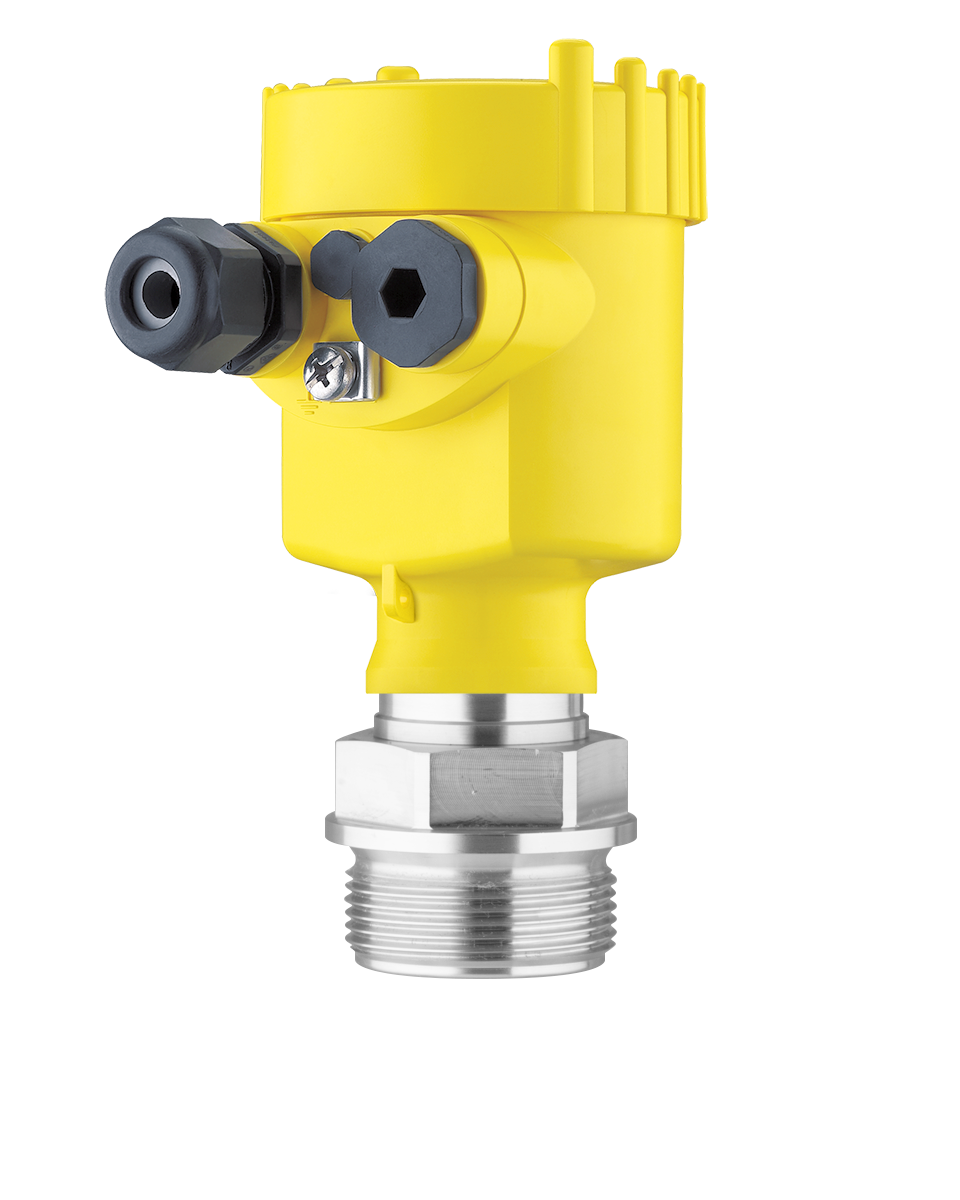

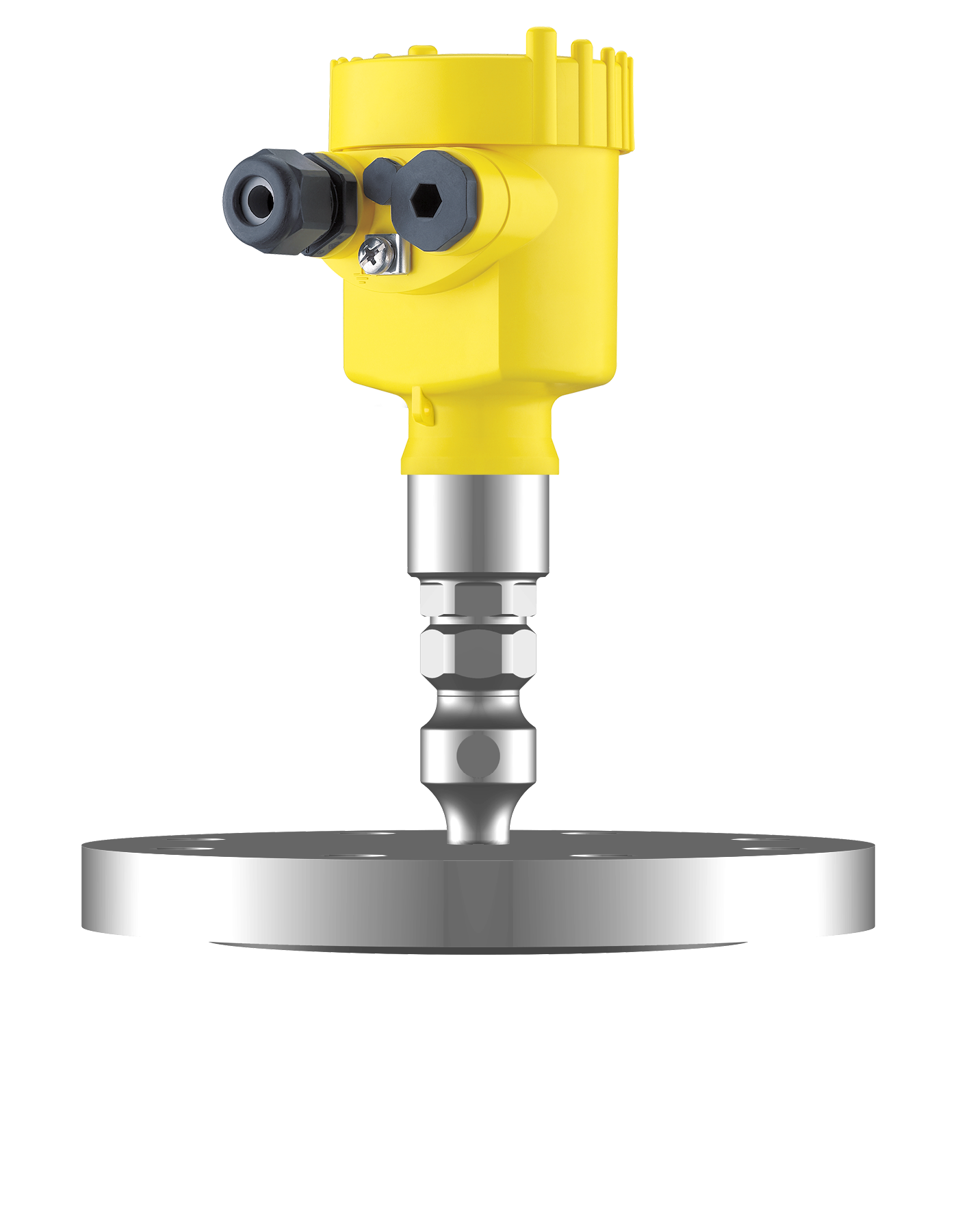

Sensors with metallic measuring cell

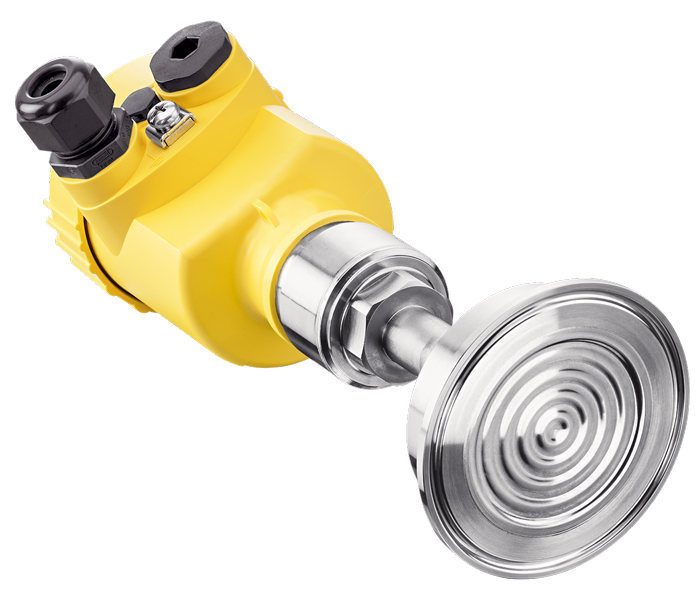

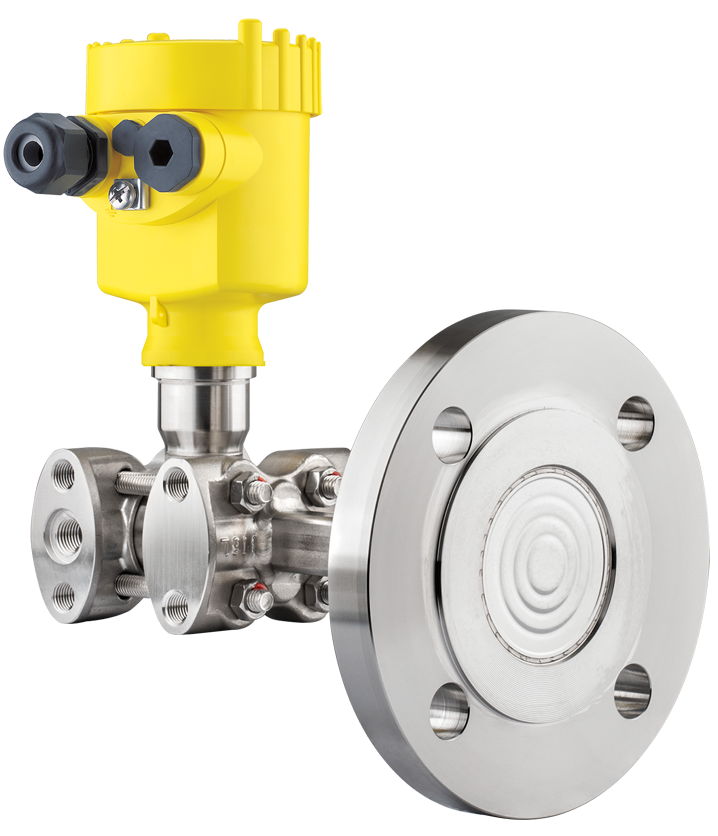

Sensor with chemical seal

VEGABAR BASIC

and 360° status display

VEGABAR PRO

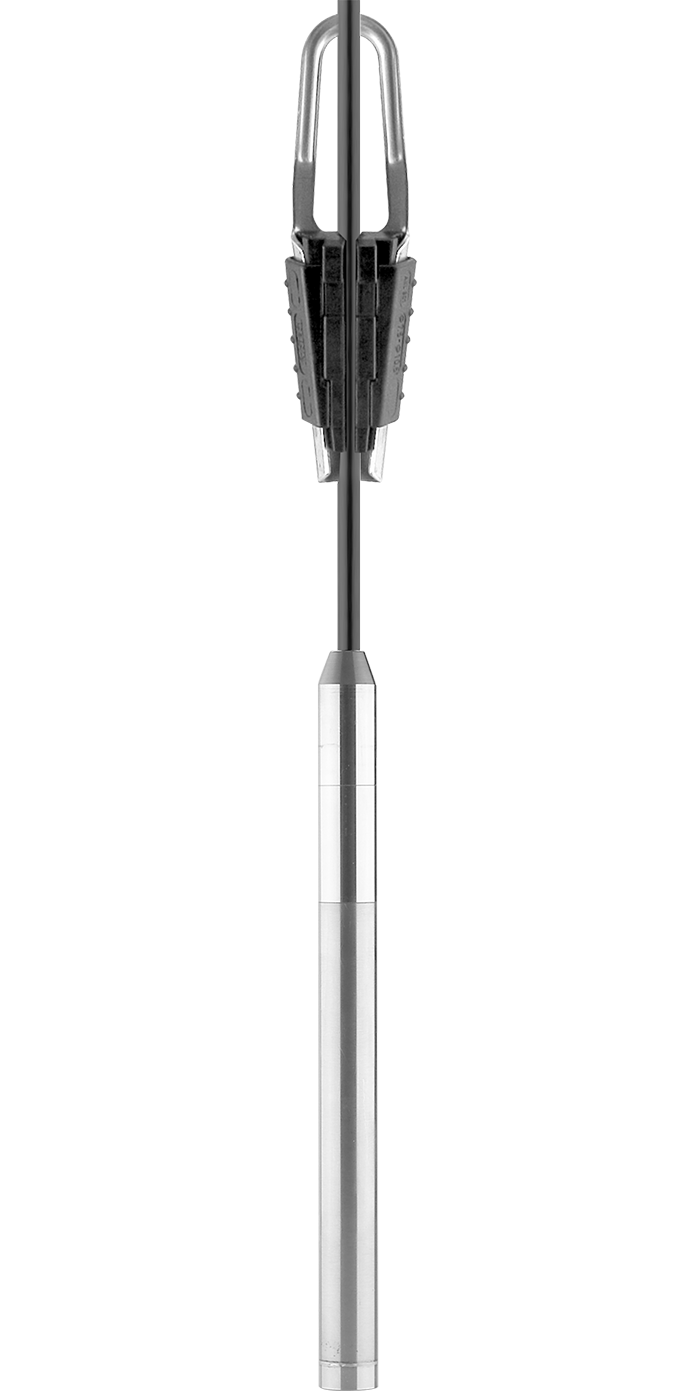

Submersible pressure transmitter

Pressure overlay in the vessel

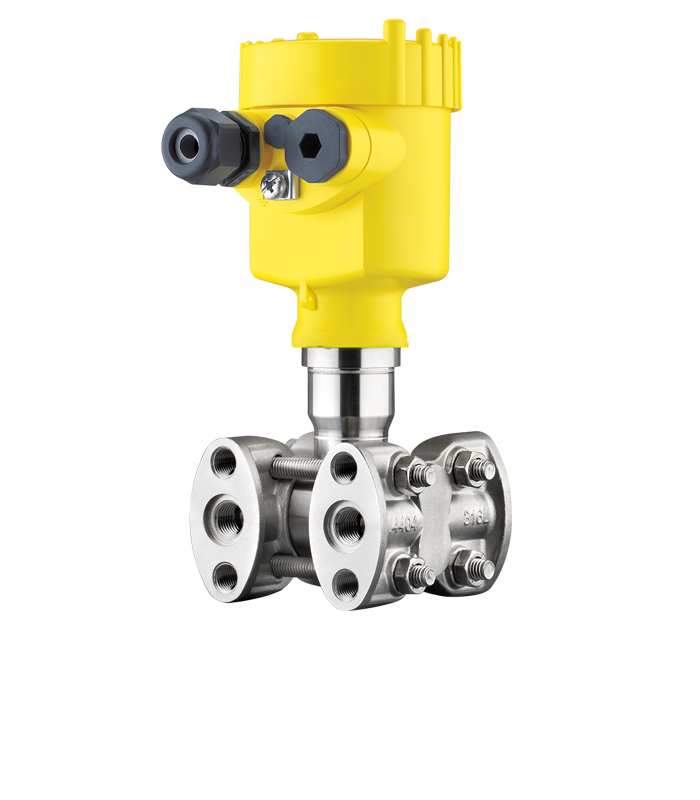

Mechanical differential pressure sensors

A metallic measuring cell is used as the sensor element.

The advantages:

+ High static pressures

+ Compact design

+ High measurement accuracy

+ Can measure extremely small pressure differences

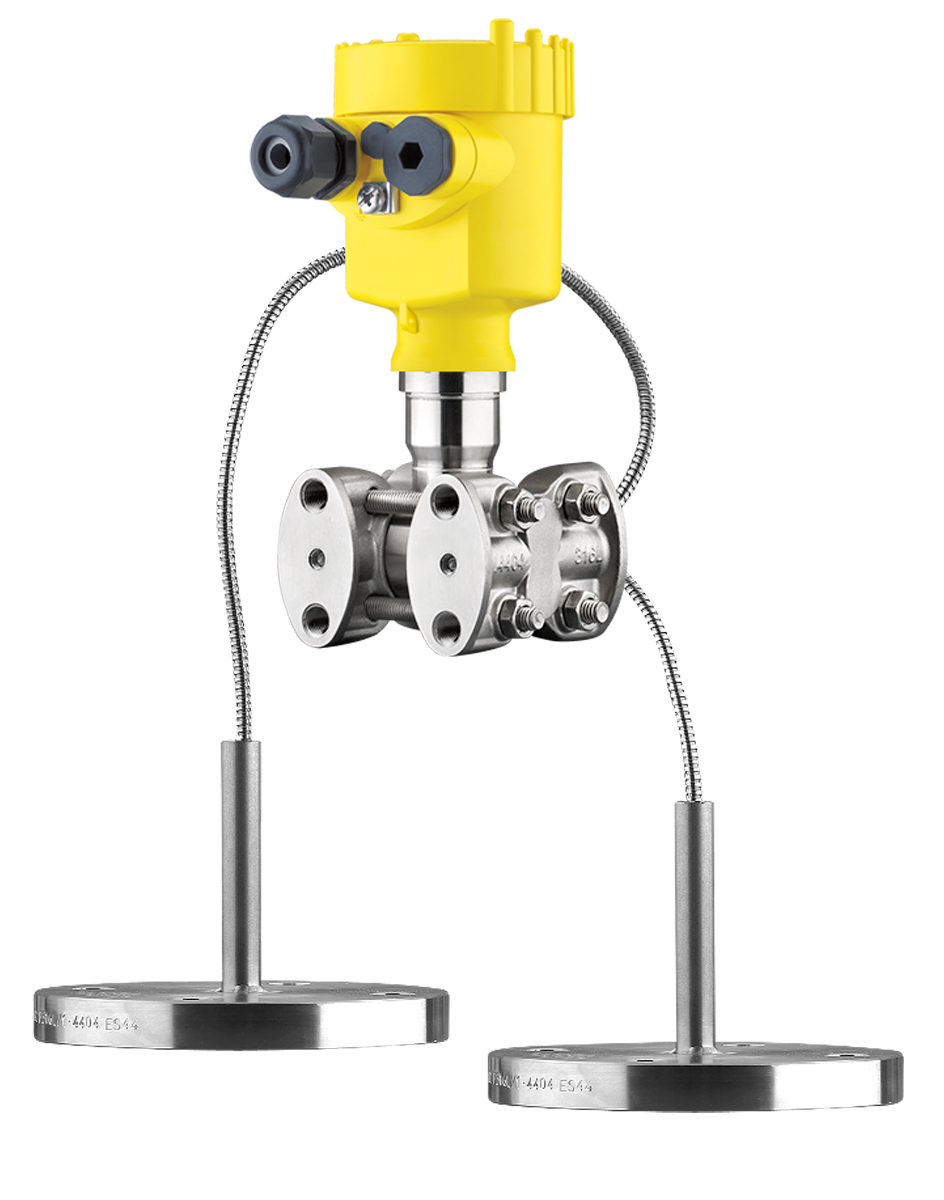

Electronic differential pressure sensors

Two pressure transmitters from the VEGABAR PRO series combine to form a system

The advantages:

+ Unaffected by environmental factors or differences in ambient temperature

+ Use of different configurations and measuring cells

+ Minimal installation, assembly and maintenance effort

Personal consultant

Enter your zip to find your personal consultant.

{{contact.DisplayName}}

{{contact.StakeHolderType}}

Callback service

Ask for one of our experts to call you back.

Request a return callIn urgent service cases, please contact us directly via our 24-hour service hotline.

Close