To reliably detect the level in a vessel, the reflection signal from the medium must be clearly distinguishable from the noise. Two factors determine the beam angle of a radar beam – and thus its focusing – they are: the transmission frequency and the effective antenna size. If the antenna size remains the same, better focusing is achieved by

using a higher frequency.

The solution

VEGAPULS 64 operates with a transmission frequency of 80 GHz. With an 80-mm antenna, this results in a beam angle of only 3°. The radar sensor receives only distinct, definitive reflections from the product surface. This makes the measurement more accurate and reliable. By comparison: a conventional radar sensor with 26 GHz

transmission frequency and an antenna of the same size has a beam angle of approximately 10°. Due to the considerably wider signal beam, agitators, fittings or buildup on the vessel wall cause interference that can affect the measuring result.

The benefits

- Considerably easier setup and commissioning, even with complex vessel internals

- Increased measurement certainty over the entire measuring range through better focusing

- High accuracy, even when the sensor is mounted close to the tank wall

Expert tip:

For maximum measurement certainty, the largest possible antenna system should be chosen during installation. This ensures both optimal focusing and maximum signal strength.

Applications

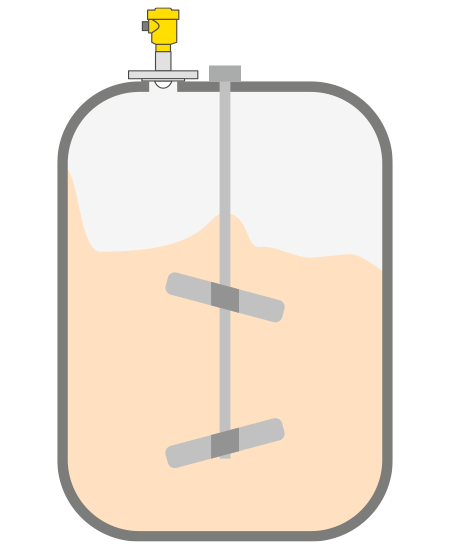

Dissolving tank

Level measurement in a dissolving tank

The precursors for the manufacture of colour pigments are dissolved in the dissolving tank. These precursors are mainly Naphtha based, and, depending on the formulation, water and sodium hydroxide solution are added as solvents for the production of the basic pigment solution. An agitator ensures uniform mixing of substances as they are added. The level measuring system is needed to ensure reliable values that are delivered to the control system.

Reliable

Measurement is independent of the process conditions

Cost effective

Reliable, maintenance-free operation

User friendly

Simple installation from above through a small opening

Mixing tank for soft cheese production

Mixing tank for soft cheese production

In the production of soft cheeses, various types of cheese are mixed and melted in a mixing tank. The cheese collects on the walls of the tank and is scraped off again by large spatulas. To ensure efficient production of the soft cheese, reliable level measurement is required.

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Easy cleaning without dismantling

User friendly

Simple setup and commissioning

Aroma vessel

Level measurement in an aroma vessel

A wide variety of aromas and flavourings are used in the food industry. The containers which store these ingredients until further processing often have small dimensions and internal obstructions. They are cleaned several times a day during batch changes. Level measurement is essential for cost-effective stocking of these ingredients.

Reliable

Reliable measurement for all liquid media

Reliable measurement for all liquid media

plics® concept: short delivery time and standardized operation

User friendly

Reliable measurement even with internals

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}