Measuring principles for pressure measurement

Measuring principles for pressure measurement

In a nutshell: Pressure instrumentation

With the help of pressure measurement technology, vacuum, process pressure, and differential pressure as well as level, volume, density and flow can be measured.

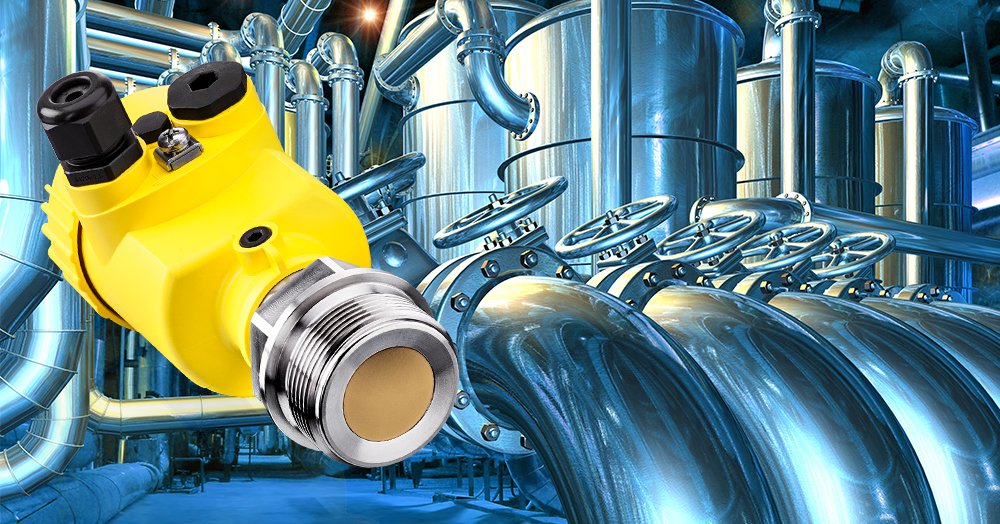

The pressure of the measured medium deflects the diaphragm on a pressure transmitter's measuring cell, which then converts it into an electronic signal. The measuring range extends from very low pressures from 0 to 25 mbar up to extreme pressures of up to 1,000 bar at process temperatures from -20 to +400 °C.

How does that work? VEGA has developed a variety of measuring cells that are specially adapted to specific measurement conditions:

- Ceramic-capacitive CERTEC® measuring cell with either absolutely front-flush or recessed diaphragm

- Chemical seal system is for decoupling the transmitter away from high temperatures or aggressive media

- Differential pressure measuring cell: Piezoresistive metallic measuring cell with integrated overload diaphragm

- Metallic measuring cells

What types of pressure measurement are there?

The following measurement tasks can be accomplished with pressure measurement technology:

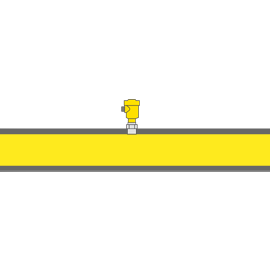

- Process pressure measurement

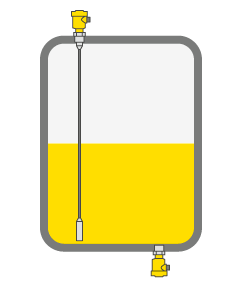

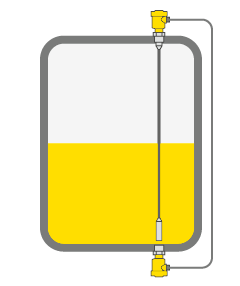

- Hydrostatic pressure measurement for level monitoring

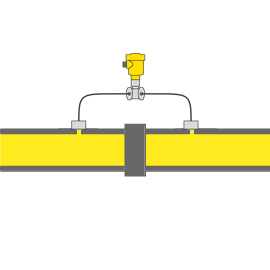

- Differential pressure measurement for determining pressure, level, volume, density and flow rate

Which pressure transmitter is the right one depends on where it is to be used. We’re happy to assist you in finding the most suitable pressure measurement technology for your application.

What are the advantages of pressure measurement technology from VEGA?

What requirements must pressure transmitters meet?

Safety and efficiency always have top priority in complex processes. In order to achieve the highest quality and productivity, pressure measurement technologies must be capable of meeting the wide-ranging requirements of different industries.

VEGA has the right pressure transmitter for every application:

- Temperature shock compensation: Measuring results unaffected by rapid temperature changes

- Extremely small measuring ranges: very high measurement accuracy from 25 mbar and up

- Ceramic measuring cell for pressures up to +100 bar: front-flush mounting, even with abrasive media

- Electronic differential pressure: A differential pressure system can be set up with any sensor pairing from the VEGABAR 80 series

- Second Line of Defense: absolutely gas-tight, encapsulated process module

Pressure transmitters from VEGA can also be used in these areas:

- Hazardous zones and safety-related systems up to SIL2 or SIL3 in redundancy

- Chemically aggressive media

- Strict hygienic applications in the food and pharmaceutical industries, with fully certified materials and process fittings

Related articles

Stock preparation for cartonboard machine modernised with VEGABAR sensor technology

Read more

VEGABAR 38 reliably measures the pressure in emulsion lines and prevents pump failure

Read more

Pressure measurement in the ozone collection pipe

Read more

Pressure transmitter with ceramic CERTEC® measuring cell meets the stringent demands of the pharmaceutical industry

Read more

7 good reasons for using pressure transmitters with ceramic measuring cell

Read more

Pressure transmitters with wear-free ceramic CERTEC® measuring cells can compensate for temperature shocks

Read moreDiscover high-quality solutions for measuring pressure in your industry

Water and wastewater

Building materials

Applications

Energy

Food industry

Mining and metal processing

Oil and gas offshore

Paper industry

Refining and petrochemical

Pharmaceutical

Ship and yacht building

Environment and recycling

Close