The radar level transmitter VEGAPULS 64 delivers reliable measurement under fluctuating process conditions

When flexibility is the company maxim

Whenever textiles need to possess special properties, it is very likely that the company CHT Germany GmbH has had something to do with it. This specialty chemicals manufacturer supplies thickening agents for textile dyes, which prevent them from running when the fabrics are printed.

Almost every one of CHT's approximately 6,000 products is tailor-made for the customer. To be able to supply its customers on time and above all with consistently high quality, the company has to operate its production very efficiently and make every step in the process reproducible. For this reason, a process control solution was transported from the manufacturing industry to the chemical industry , taking into account the special requirements of the chemical sector.

The task was to integrate a level measuring system whose measuring results would directly control the power output of the agitator motors. However, a level measurement was not required for the purpose of inventory measurement or metering, because CHT does this via weighing the raw materials. This is necessary to protect the manufacturing plant equipment.

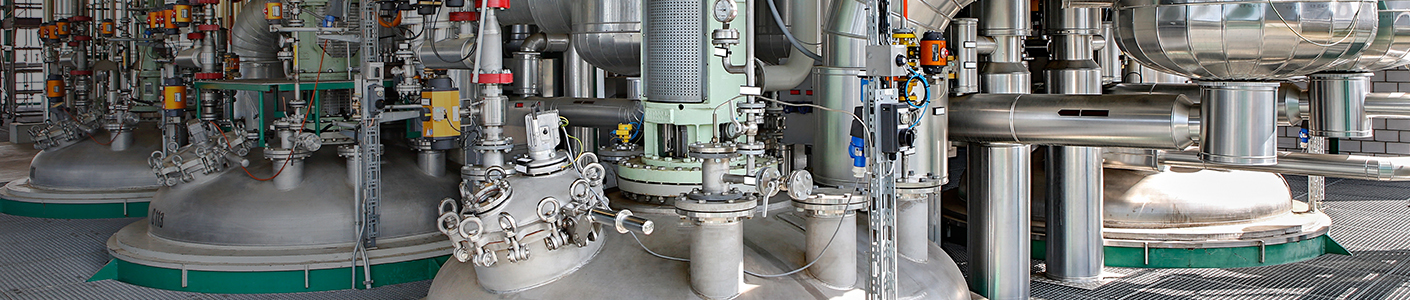

The radar level transmitter VEGAPULS 64 measures the levels in the production equipment with reliability and accuracy.

And it came on the market at just the right time. This non-contact radar level measuring instrument is characterized by extremely strong focusing and high dynamics. As a result, it measures very reliably despite build up deposits, foam, vessel internals and density fluctuations.

All in all, CHT’s collaboration with VEGA went very well, even though VEGA service technicians did have to optimize and make a lot of adjustments at the beginning before they obtained a stable measurement. In all, it took less than two weeks for the radar level transmitter to be installed, precise measuring results to be output and the data to be integrated into the APROL system.

Now, the sensor can measure and follow the level perfectly even when the agitators are switched on.

Aplikacje

Eksportuj ten artykuł

Pobierz jako PDFUdostępnij post

Komentarze ({{comments.length}})

{{getCommentAuthor(comment, "Anonim")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}