Fast delivery

Wide variety of mounting options

Simple setup and commissioning

Reliable measurement

Sensors for the water and wastewater industry

With fixed cable connection

With cable connection compartment

With fixed cable connection

Protection IP66/IP68, Type 6P

With cable connection compartment

Protection IP66/IP67, Type 4X

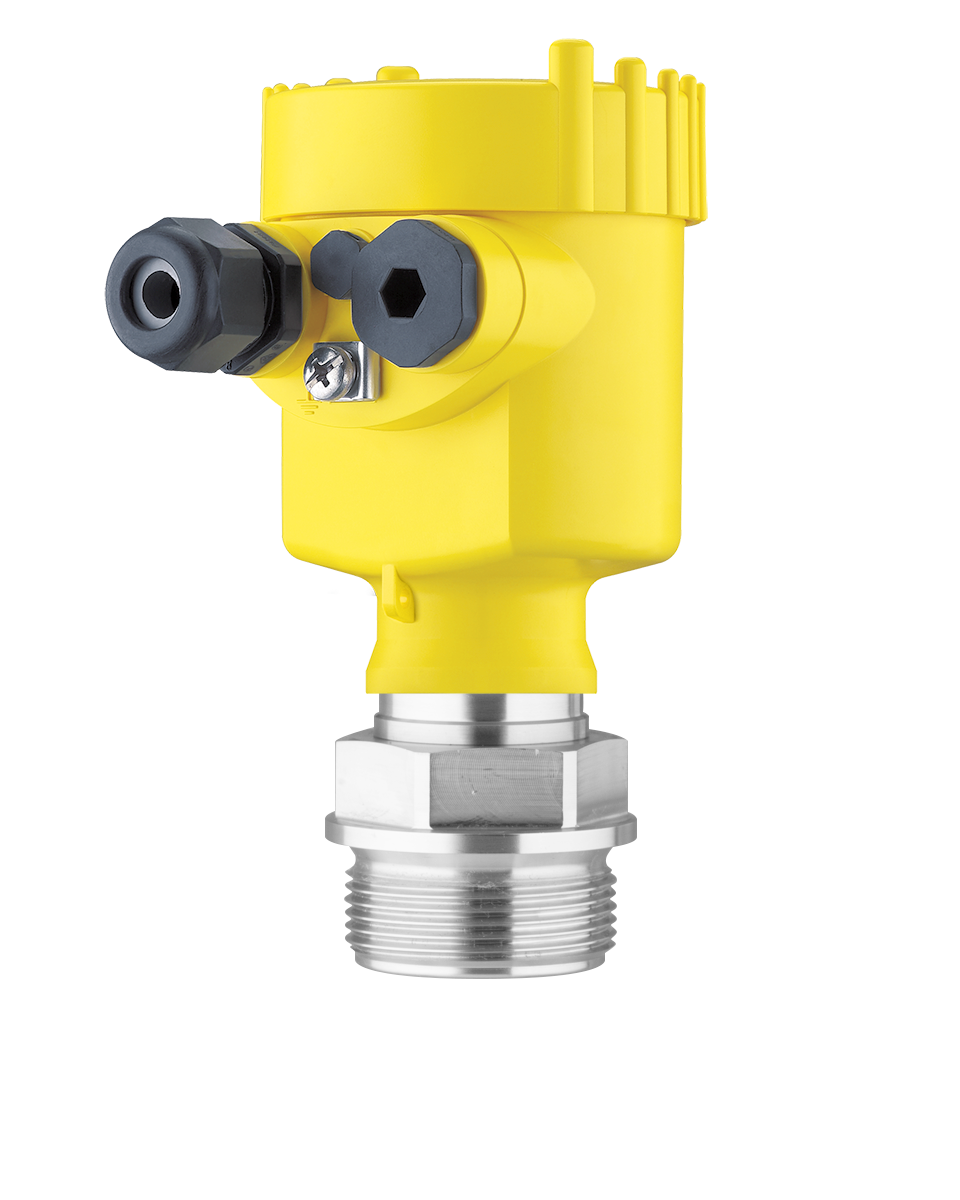

Process pressure measurement

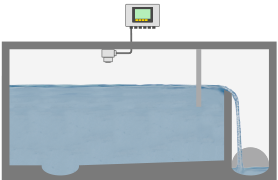

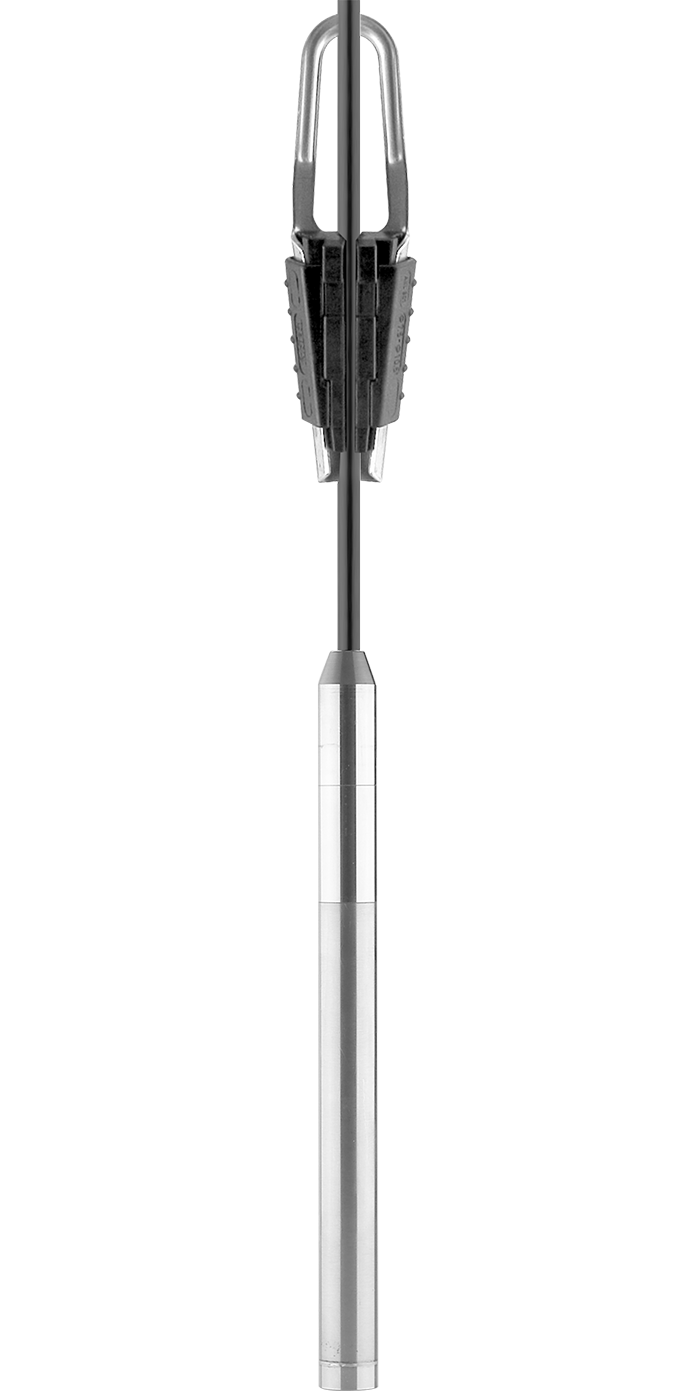

Hydrostatic pressure measurement

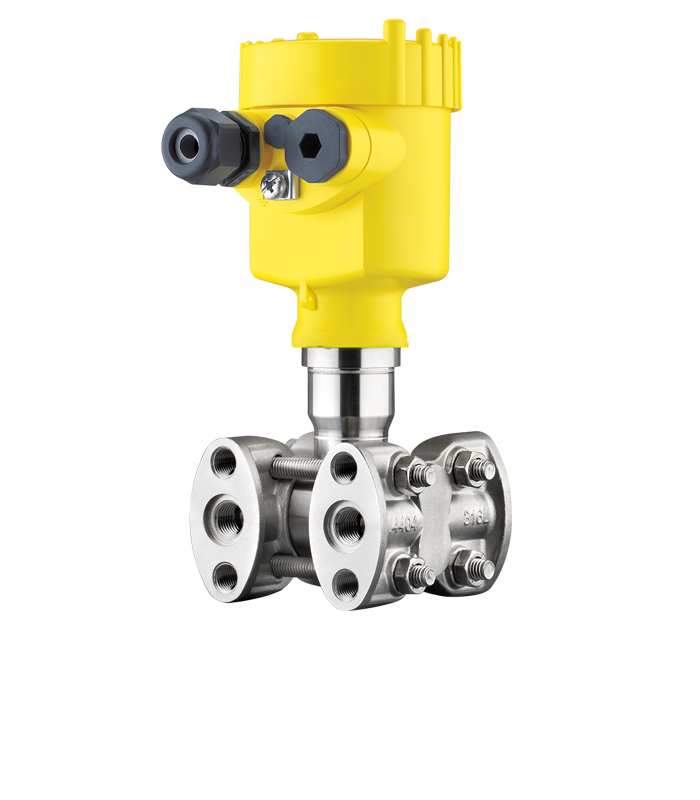

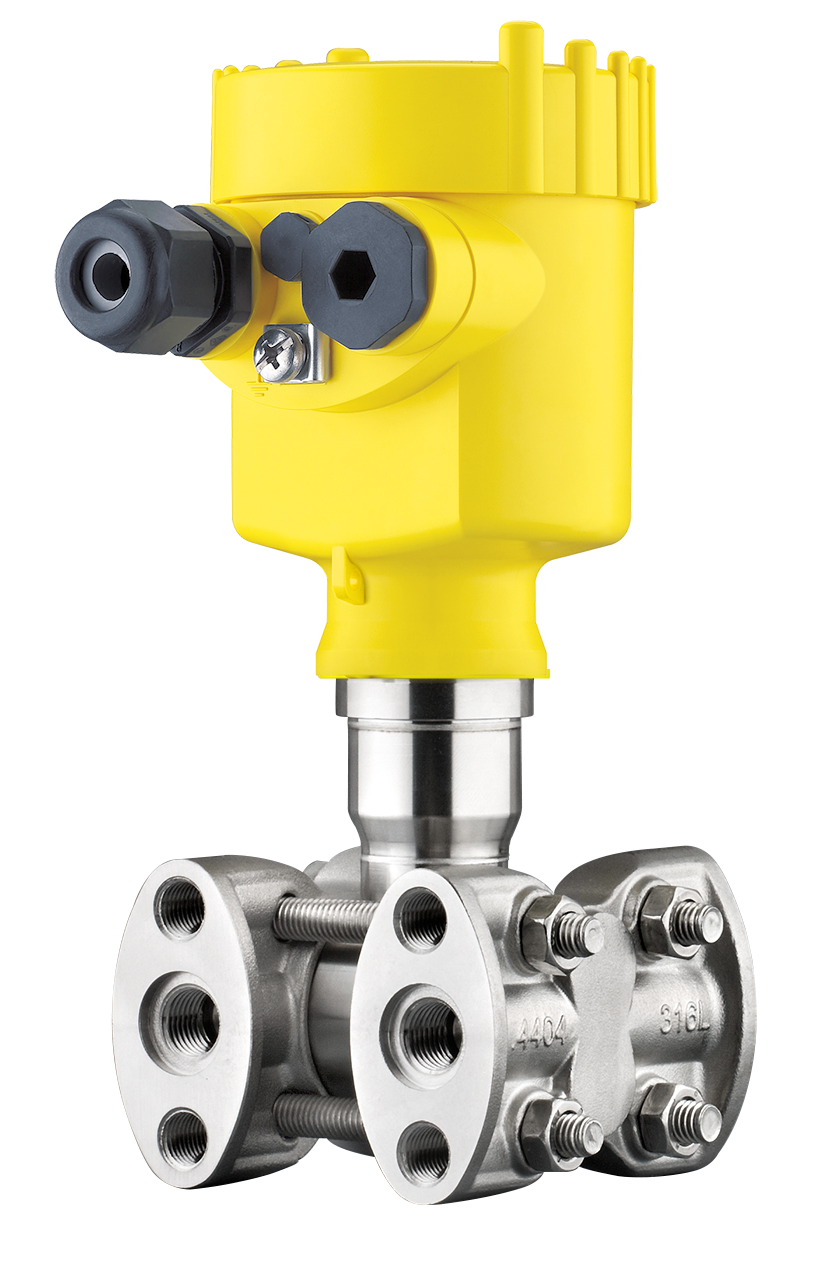

Differential pressure measurement

Process pressure measurement

Hydrostatic pressure measurement

Differential pressure measurement

VEGAMET 841, 842, 861, 862

VEGAMET 841, 842, 861, 862

for analogue or digital sensors, data loggers,

field housings

field housings

VEGA Brasil Indústria e Comércio Ltda.

Rua Werner Von Siemens, 111 Prédio 19 E-5

05069-900 LAPA, São Paulo

Brazil

Close