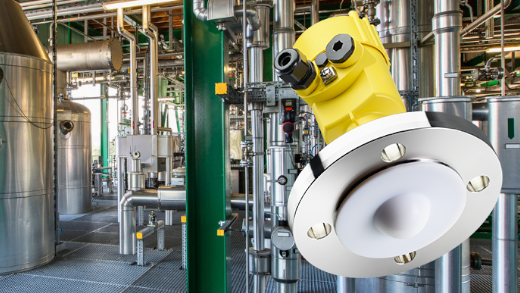

VEGAPULS radar transmitters

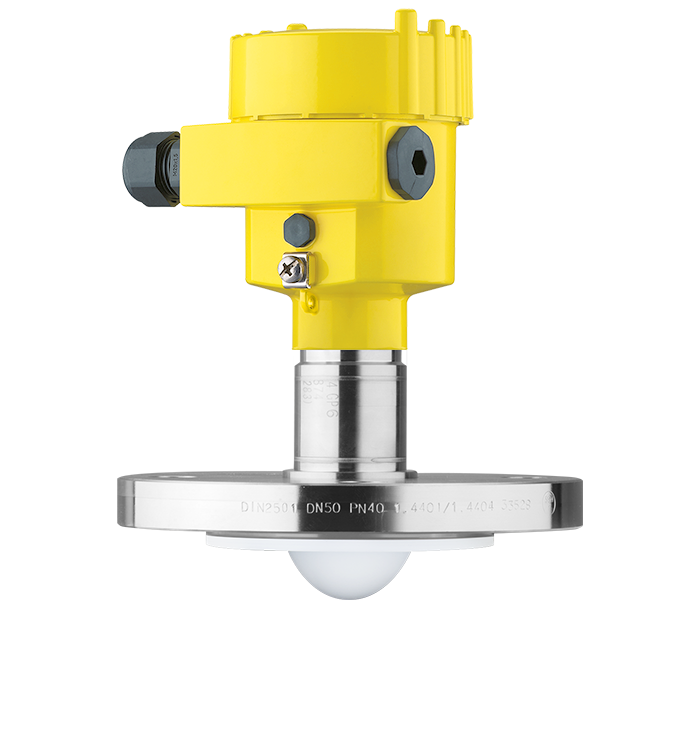

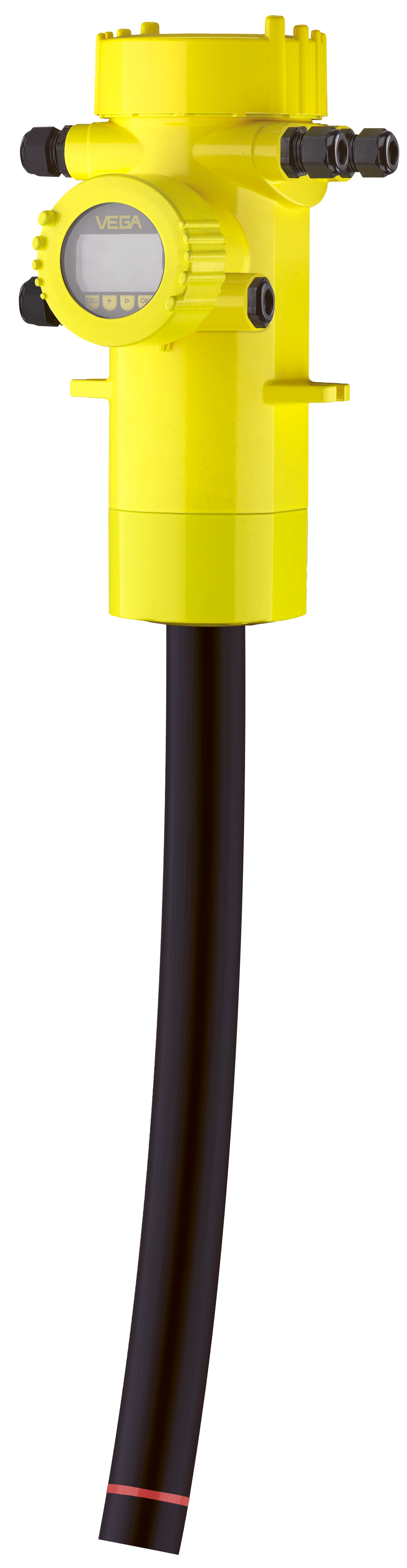

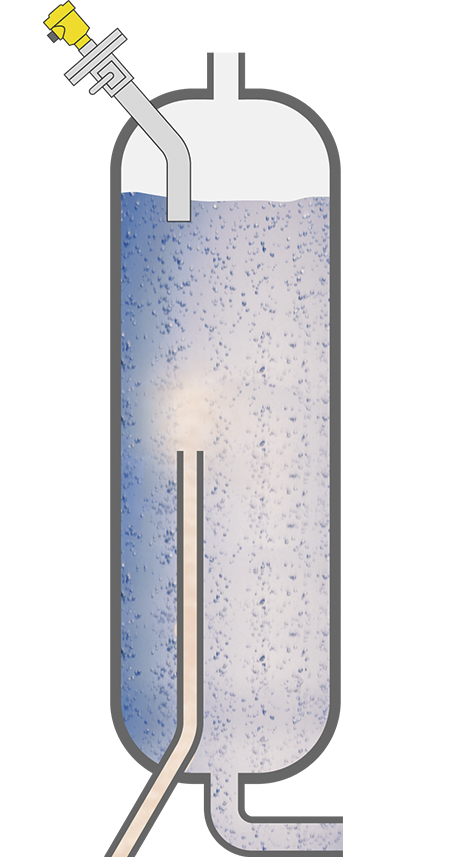

Radiometric transmitters

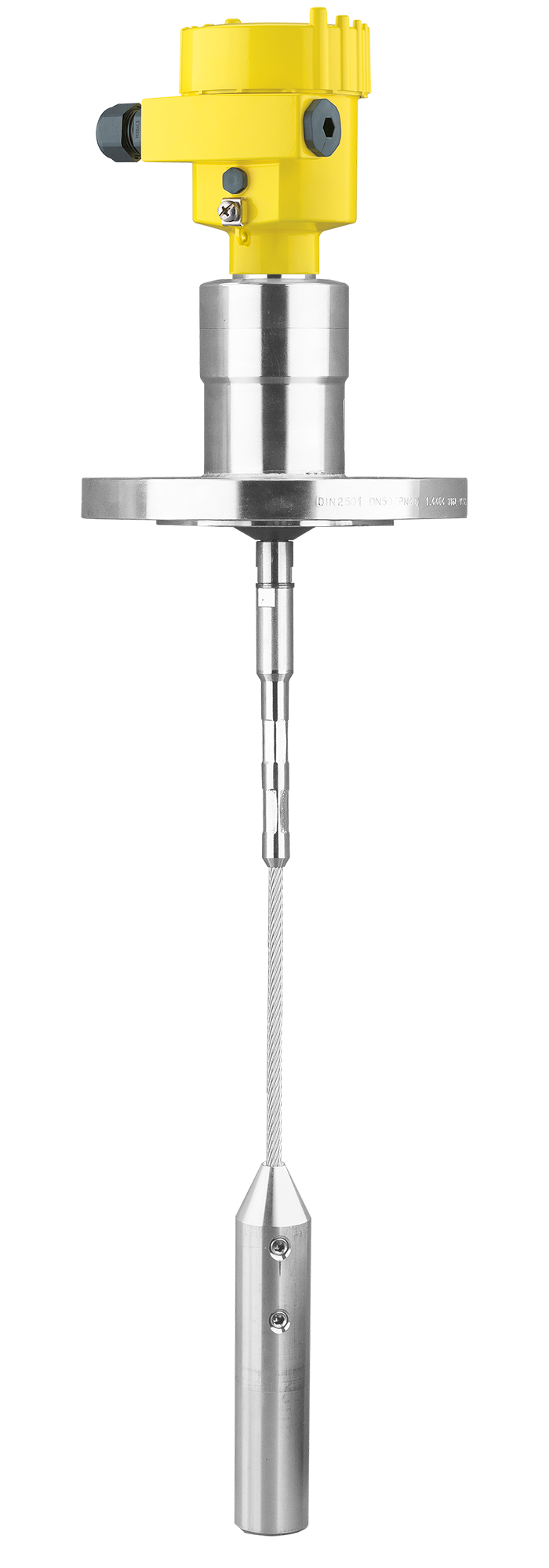

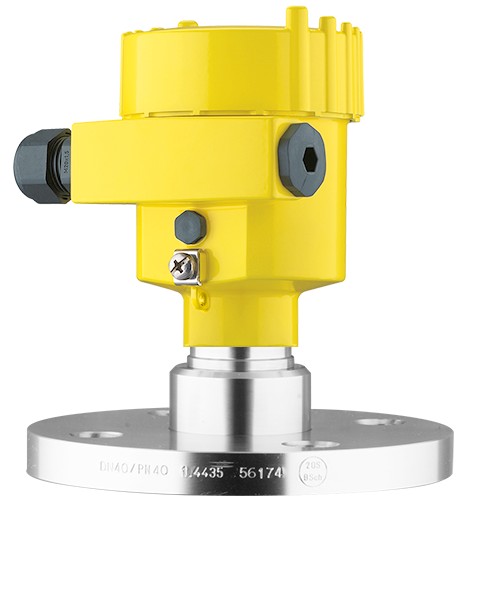

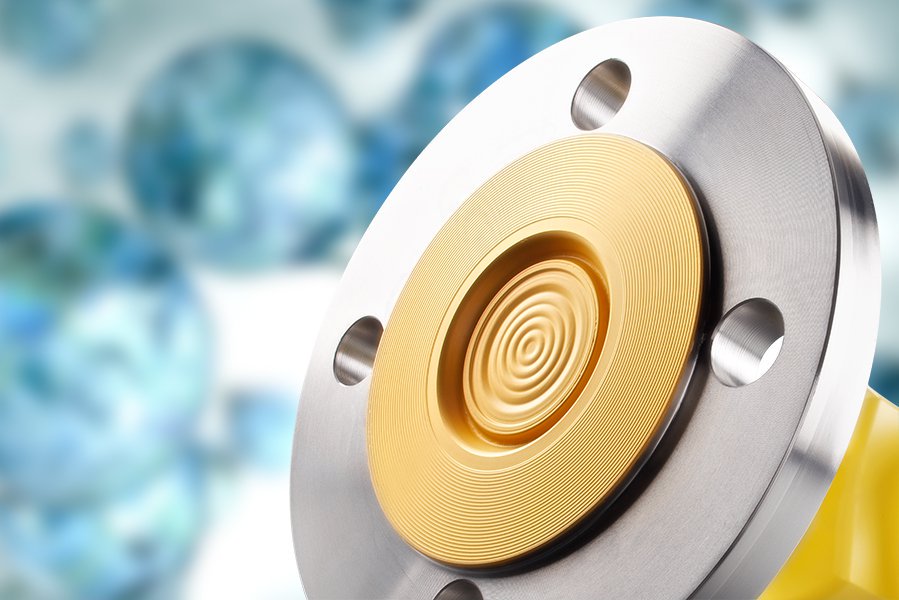

VEGAFLEX GWR transmitters

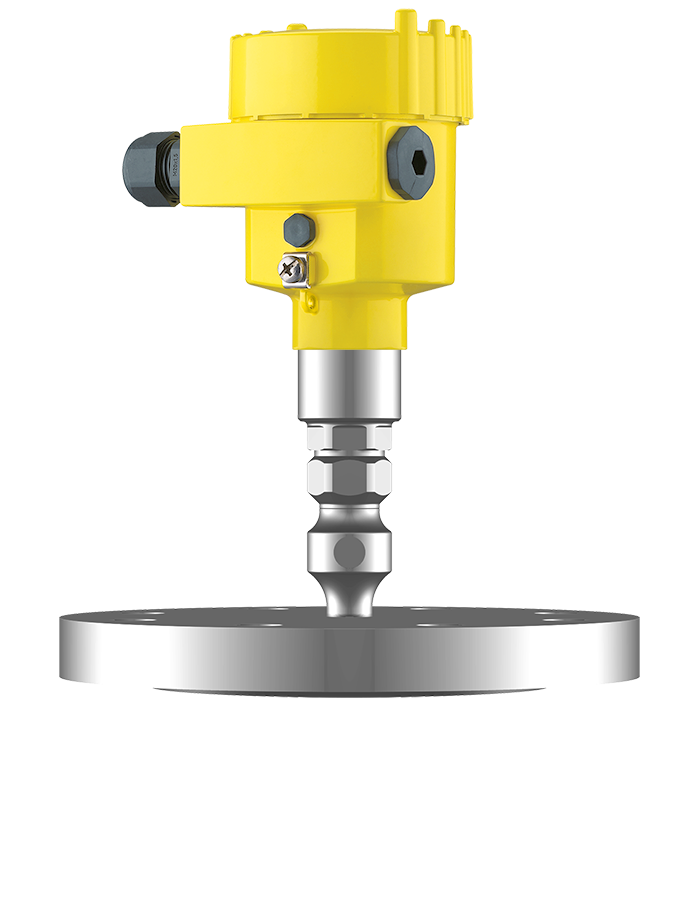

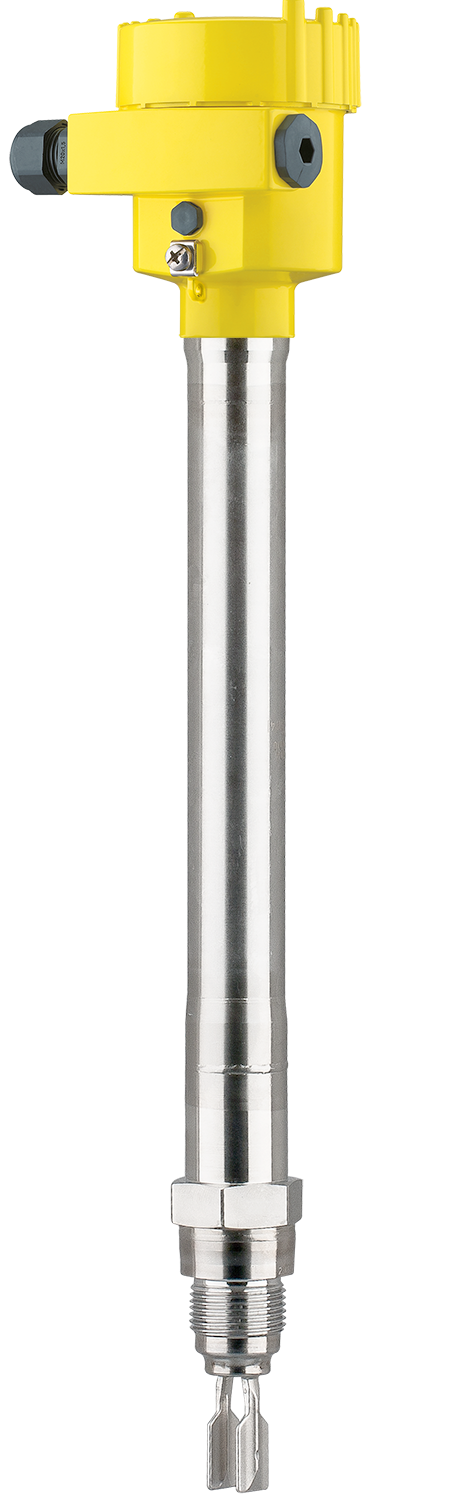

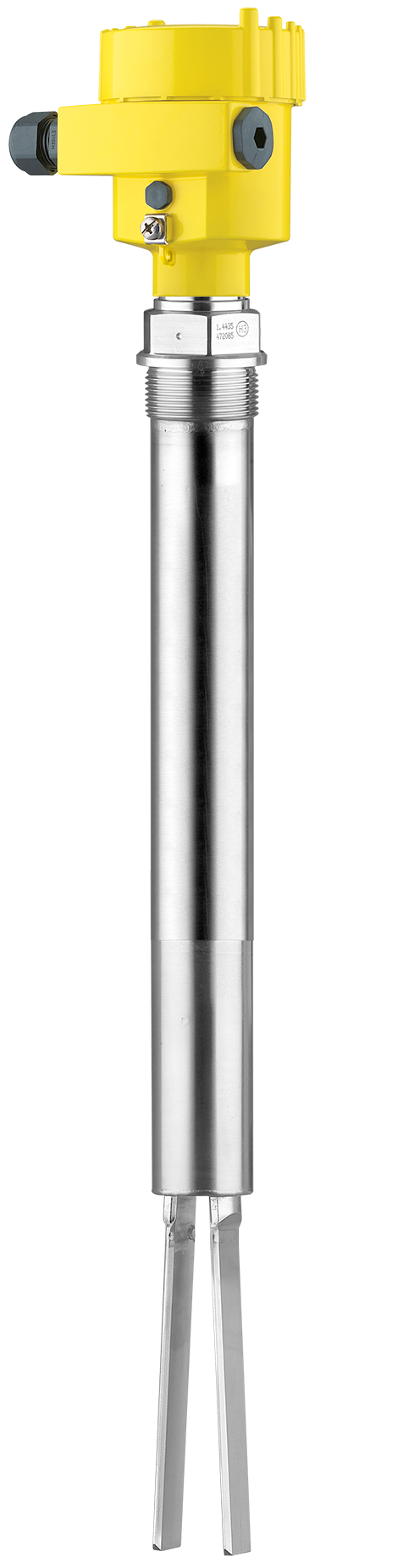

Vibrating level switch

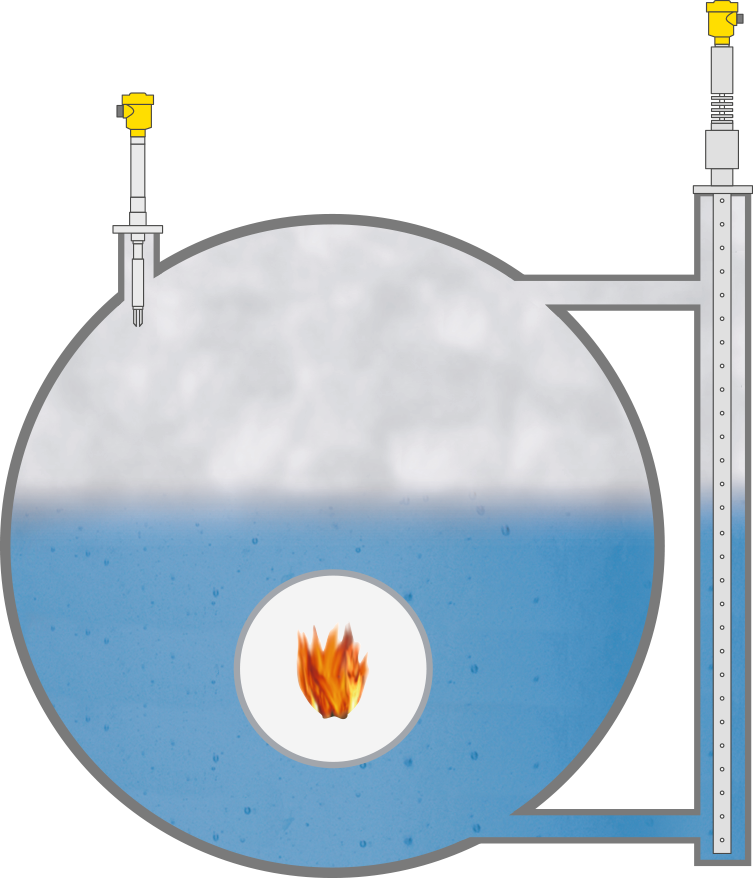

Capacitive and radiometric

Personal consultant

Enter your zip to find your personal consultant.

{{contact.DisplayName}}

{{contact.StakeHolderType}}

Call-back service

Ask for one of our experts to call you back.

Request a return callIn urgent service cases, please contact us directly via our 24-hour service hotline.

News & events from the chemical industry

Blog articles on the topic of chemicals production

Videos on the topic of chemicals production

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Close