High-frequency radar level technology on the rise

In 2014 a new sensor for the continuous measurement of bulk solids, VEGAPULS 69, was introduced with great success. This sensor also operates with a transmission frequency 3 times higher than the widely used 26 GHz frequency.

New radar level sensor VEGAPULS 64 for liquids: The smallest antenna is no bigger than a 1 Euro coin, so that the new measuring instrument is an ideal solution for installation in small containers.

VEGAPULS 64 for liquid applications followed in the spring of 2016, likewise setting a milestone in measurement technology with its high dynamics and superior focusing. "Media with poor reflective properties, i.e. low dielectric constant, can now be measured significantly better than with previous radar sensors," continues Skowaisa. Thanks to the vastly better focusing, the beam simply passes by internal tank installations or buildup. Interfering signals, which previously had to be filtered out with false signal suppression, now play hardly any role in the measurement process.

"Moreover, it is now possible to use a much smaller antenna. Today we have process fittings with an antenna diameter of only ¾" – equivalent to the size of a 1-euro coin." The new technology also allows precise measurement of the level very close to the tank bottom. This opens up new perspectives in determining the level in small containers used in the pharmaceutical and biotech industries, as well as determining the amount of fuel left at the bottom of large fuel tanks. Measurement accuracy is +/-2 mm, even with a working range up to 30 m.

The great success of bulk solids radar sensor VEGAPULS 69 and the current market launch of VEGAPULS 64 for liquids are setting the agenda for the future technological development of radar level measurement. "Today, there is no way to surpass the performance of radar measurement based on an operating frequency of 80 GHz," says Skowaisa with conviction. Discover 80 GHz

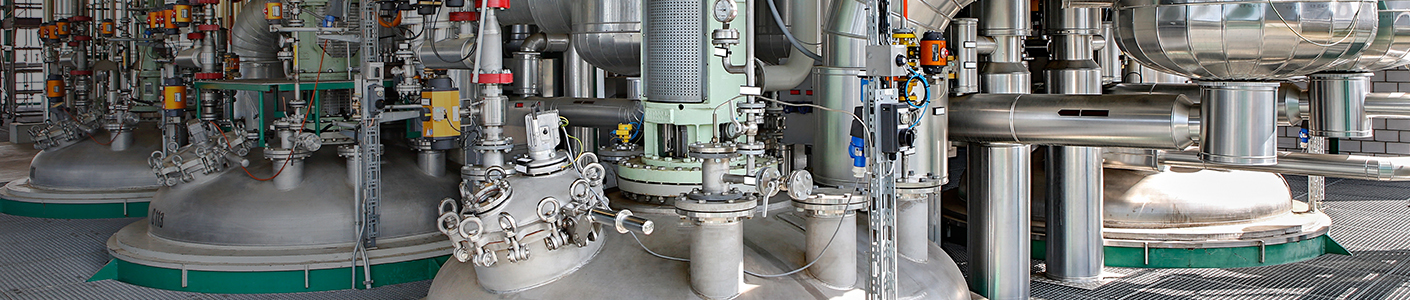

Industries with lots of application possibilities

Aplicações

Gêneros alimentícios

Indústria de cimento

Indústria farmacêutica

Refinaria e petroquímica

Construção de navios e iates

Agregados

Mineração e Metalurgia

Offshore de óleo e gás

Energia

Exportar este artigo

Baixar como PDFCompartilhar post

Comentários ({{comments.length}})

{{getCommentAuthor(comment, "Anônimo")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}